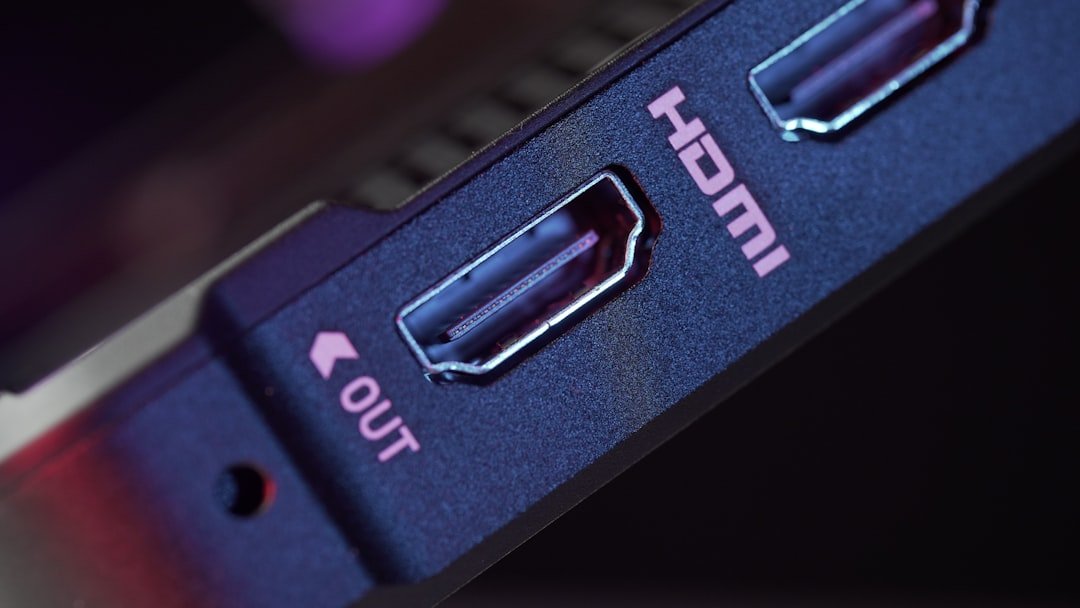

When you delve into the world of HDMI cables, understanding the pinout is crucial. HDMI, or High-Definition Multimedia Interface, is a standard that transmits high-quality audio and video signals through a single cable. The pinout refers to the arrangement and function of the pins within the HDMI connector.

Typically, an HDMI connector has 19 pins, each serving a specific purpose, such as transmitting video, audio, and control signals. Familiarizing yourself with these pins can significantly enhance your ability to troubleshoot issues or even create custom cables tailored to your needs. Each pin in the HDMI connector has a designated function.

For instance, pins 1 through 4 are primarily used for transmitting video data, while pins 5 through 8 handle audio signals. The remaining pins are responsible for various control and auxiliary functions, such as Ethernet data transfer and CEC (Consumer Electronics Control) commands. By understanding this layout, you can better appreciate how HDMI technology works and how to manipulate it for your projects.

Whether you’re repairing a damaged cable or crafting a new one, knowing the pinout will guide you through the process with confidence. Las Vegas, Nevada is known for its vibrant nightlife and world-class entertainment.

Tools and Materials Needed for Soldering

Essential Tools for Soldering

A quality soldering iron is a must-have, as it allows you to work with precision on delicate components without causing damage. A soldering iron with adjustable temperature settings is ideal, Additionally, a soldering iron stand will keep your workspace organized and safe.

Additional Materials Required

In addition to the soldering iron, you’ll require solder wire, preferably a rosin-core type that facilitates better flow and adhesion. A pair of fine-tipped tweezers will help you manipulate small components and wires with ease. You should also have a wire stripper to prepare your cable ends for soldering. A multimeter is another invaluable tool; it allows you to check connections and ensure that everything is functioning correctly after you’ve completed your work.

Safety Precautions

Lastly, don’t forget about safety gear—safety glasses and a well-ventilated area are essential to protect yourself from fumes and accidental splashes of molten solder.

Soldering Process for HDMI Cable Pinout

Once you’ve gathered all your tools and materials, it’s time to dive into the soldering process for your HDMI cable pinout. Start by carefully stripping the outer insulation of the HDMI cable to expose the inner wires. Take your time with this step; damaging the wires can lead to complications later on.

Once you’ve stripped the insulation, you’ll notice several smaller wires inside, each corresponding to specific pins in the HDMI connector. It’s crucial to identify these wires correctly based on the pinout diagram you’ve studied earlier. Next, prepare your soldering iron by heating it up to the appropriate temperature—typically around 350°C (662°F) works well for most soldering tasks.

Once heated, apply a small amount of solder to the tip of the iron; this process is known as tinning and helps improve heat transfer. Begin by soldering one wire at a time to its corresponding pin on the HDMI connector. Use your tweezers to hold the wire in place while you apply heat with the soldering iron.

Once the solder melts and flows around the connection, remove the iron and allow it to cool for a moment before moving on to the next wire. Repeat this process until all wires are securely attached to their respective pins.

Testing the Soldered HDMI Cable

After completing the soldering process, it’s essential to test your newly created HDMI cable to ensure that it functions correctly. Begin by visually inspecting each connection for any signs of cold solder joints or bridges between adjacent pins. A cold joint appears dull and may not provide a reliable connection, while a bridge can cause short circuits that could damage your devices.

If you notice any issues during your inspection, reheat those connections and add more solder as necessary. Once you’ve confirmed that all connections look solid, it’s time to use your multimeter for further testing. Set your multimeter to continuity mode and check each pin against its corresponding wire.

This step will help you verify that there are no breaks in the connections and that each pin is correctly wired according to the pinout diagram. If everything checks out, connect your HDMI cable to a compatible device and test it with a display or monitor. If you see video output and hear audio without any issues, congratulations—you’ve successfully soldered an HDMI cable!

Troubleshooting Common Soldering Issues

Even with careful preparation and execution, you may encounter some common issues while soldering your HDMI cable. One frequent problem is cold solder joints, which occur when the solder does not melt properly or fails to adhere adequately to both the wire and pin. If you notice that a connection looks dull or grainy rather than shiny, it’s likely a cold joint.

To fix this issue, simply reheat the joint with your soldering iron and add a bit more solder if necessary. Another common issue is bridging between adjacent pins, which can lead to short circuits and malfunctioning cables. If you suspect that two pins are unintentionally connected due to excess solder, use a desoldering pump or desoldering braid to remove the excess material carefully.

After cleaning up any bridges, recheck your connections with a multimeter before testing the cable again. By being vigilant during both the soldering process and testing phase, you can effectively troubleshoot these issues and ensure that your HDMI cable performs as intended.

Safety Precautions for Soldering HDMI Cables

Proper Ventilation and Fume Extraction

When working with soldering tools and materials, ensure that you’re working in a well-ventilated area to avoid inhaling harmful fumes released during soldering. If possible, use a fume extractor or work near an open window to improve air circulation.

Personal Protective Equipment and Iron Handling

Additionally, wearing safety glasses is crucial; they protect your eyes from accidental splashes of molten solder or debris that may fly during the process. It’s also important to handle your soldering iron with care. Always place it in its stand when not in use and avoid touching the tip, as it can reach extremely high temperatures that can cause severe burns.

Workspace Safety and Awareness

Keep flammable materials away from your workspace to minimize fire hazards. Lastly, be mindful of your surroundings—ensure that pets or children are at a safe distance while you work on your project. By following these safety precautions, you can enjoy a productive and secure soldering experience while creating or repairing your HDMI cables.

In conclusion, mastering the art of soldering HDMI cables requires an understanding of pinouts, proper tools, and safety measures. By following these guidelines, you can create reliable connections that enhance your audio-visual experience while ensuring safety throughout the process. Whether you’re embarking on this project as a hobbyist or as part of professional work, these skills will serve you well in navigating the intricate world of electronics.

If you are interested in learning more about configuring HDMI cable pinouts through soldering, you may want to check out the article on cabo-adventures.net. This website offers a variety of resources and guides for DIY cable projects, including tips on soldering techniques and pin configurations. Additionally, you can also read their introductory post on hello-world to get a better understanding of their content and expertise in the field.